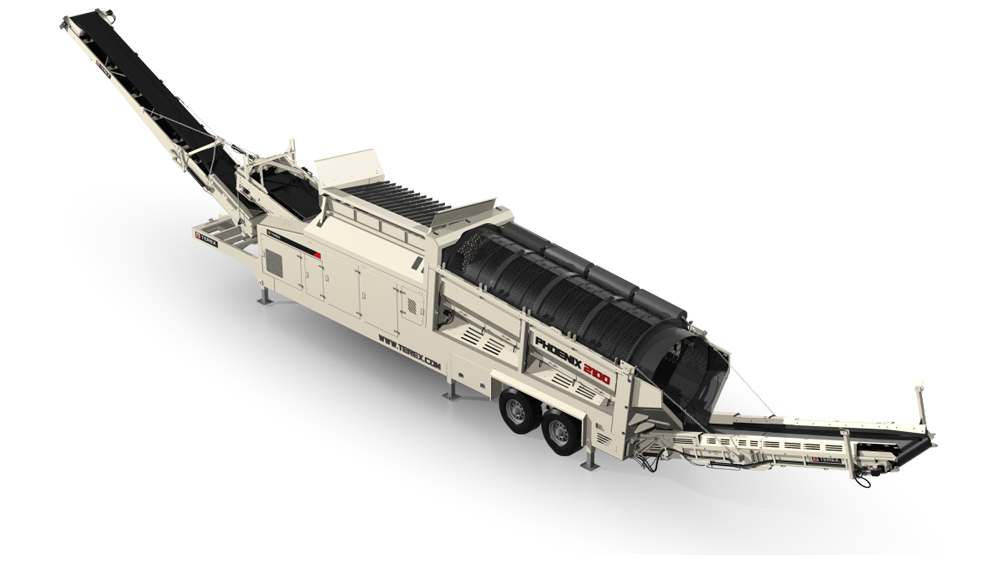

The Powerscreen® Phoenix 3300 is a 2-way split mobile trommel screen designed and built specifically for topsoil, recycling, wood chippings and compost applications. Key features of the Phoenix 3300 include a large screen area, a low maintenance 4 wheel drum drive system, proportional load sensing on the feeder conveyor to eliminate blockages and downtime, hydraulic folding conveyors including a 180° radial fines conveyor and tier 3 compliant engines.

The trommel screen's robust design with optional features such as a heavy duty tipping grid or double deck vibrating grid make the Phoenix 3300 the most versatile drum screen on the market today. As your trommel screen manufacturer, we've designed a machine that performs equally well in heavy C&D applications as it does in high volume compost production. The 180° swivel fines conveyor, with a 5.8m (19’-0”) discharge, means the trommel screen can generate massive stockpiles. This swivel feature can be controlled via a radio remote while the drum screen is in operation, minimizing downtime.

A powerful four wheel drive system with high performance friction grip wheels is used to turn the trommel screening drum, which gives operators the ability to run bi-directionally. Woven mesh or heavy-duty punch plate panels can be fitted to the trommel drum meaning all application requirements are met.

Caterpillar Tier 3 or Tier 4 engines combined with powerful hydraulics and auto feeder speed control mean the machine is always working at optimum level. A fifth wheel connection, triple axle bogie and a rapid setup time make the trommel screen highly mobile.